The 3D modelling and additive manufacturing laboratory is closely linked to the embedded systems and UAV laboratory. The main focus of the laboratory is to support the activities and projects of the Faculty, the University and the Biological Centre of the Academy of Sciences. We specialize in prototype design and fabrication, technology and materials research. We carry out the creation of complex 3D models, their analysis and optimization.

Lab members:

Mgr. Geyer Jakub

PhDr. Milan Novák, Ph.D.

Technology

The primary technology of the 3D modelling and additive manufacturing laboratory is 3D printing. We focus mainly to printers from the Czech manufacturer Prusa Research in the areas of FFF (fused filament fabrication) and SLA (stereolithography). We have our own modifications of these printers, e.g. Prusa i3 MK3 with double printing area or modified Prusa MMU2 (multi-material upgrade). Thanks to this we are able to print not only from common materials (e.g. PET, PLA, ABS) but also from filaments with additives (e.g. wood, carbon fiber, etc.) or more demanding materials (nylon, polycarbonate, flexible TPE/TPU, etc.) and using soluble supports. For example, we often print from PET-G with carbon fibre, FRJet (PET-G with flame retardant - flame retardant) and HT-CPE. On SLA printers, we create highly detailed parts on which we can realize specific properties (heat resistance, desired flexibility, etc.) thanks to mixing resins.

3D printing (additive manufacturing process) can also be conveniently combined with subtractive manufacturing processes (CNC, laser cutting, etc.) to realize complex prototypes.

The large-format CO2 Laser(XM1490) enables precise cutting of materials such as polycarbonate, PET or wood. It also enables engraving of these materials and glass; or, with the use of special varnishes, permanent marking/describing of metals.

Power: 150W, Max. material width: 140cm

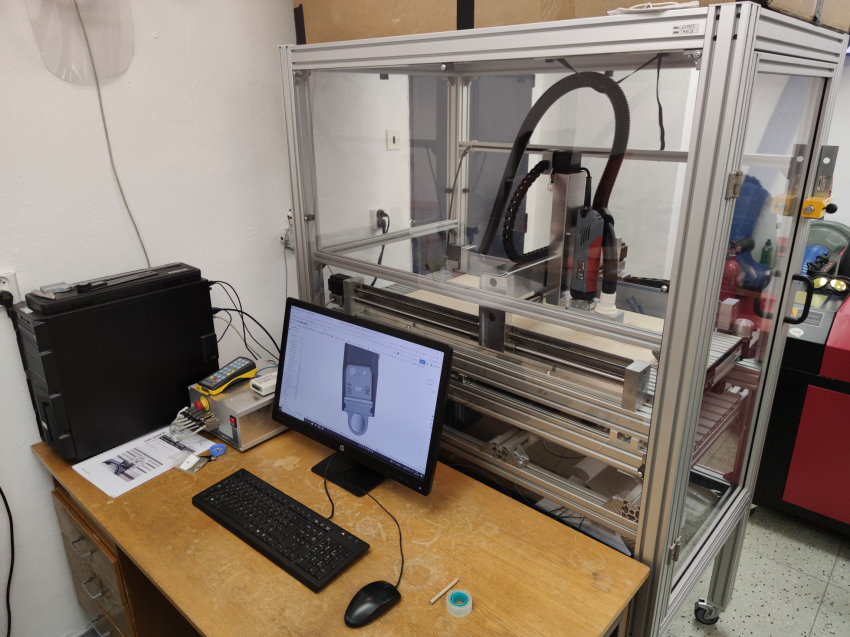

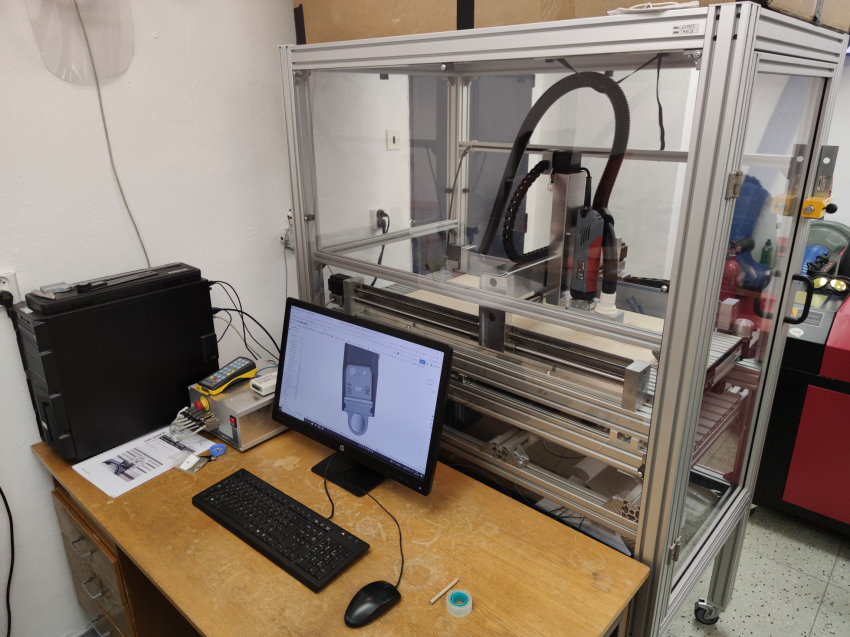

CNC milling machine(High-Z S-720/T) is used for precision machining of plastic, metal or wooden parts. It is also suitable for modification of already existing parts (drilling holes, milling pockets, etc.).

Max. area 70x40x15cm.

Software overview

OnShape, Fusion360, SolidWorks, FreeCAD, Blender, SketchUp, PrusaSlicer, Cura, Simplify3D, Meshmixer, OctoPrint, Meshroom, VXelements, ConstruCAM, WinPC-NC, LightBurn, a další

Publications and outputs

Publications

Novák M., Geyer J., et al. (2021) Construction of a Multisensor UAV System for Early Detection of Forest Pests. In: Shakhovska N., Medykovskyy M.O. (eds) Advances in Intelligent Systems and Computing V. CSIT 2020. Advances in Intelligent Systems and Computing, vol 1293. Springer, Cham. https://doi.org/10.1007/978-3-030-63270-0_78

Příručka 3D modelování a tisk pro SŠ a příručka 3D modelování a tisk pro ZŠ, Impuls pro kariéru, 2021

Patents, utility models

Patent: Digital remote control of analog potentiometers for guitar amplifier (EP 19160447.9, 2021), Ptáček L., Novák M.

Užitný vzor: Systém ke sledování kůrovcových aktivit (U1: 35641, 2021), Novák M., Ptáček L., Doležal P., Geyer J., Davídková M.

Final Thesis

Beránek Karel, Modifikace 3D tiskárny Prusa i3 MK3 na uzavřený koncept s dvojnásobnou tiskovou plochou

Čechová Jana, Tvorba 3D modelů existujících budov

Scholz Luděk, Systém pro řízení chytré domácnosti

Švarc Jakub, Konstrukce a řízení kolového robotického prostředku (probíhající)

Trtílek Ondřej, Konstrukce robotické ruky pro mobilní podvozek (probíhající)